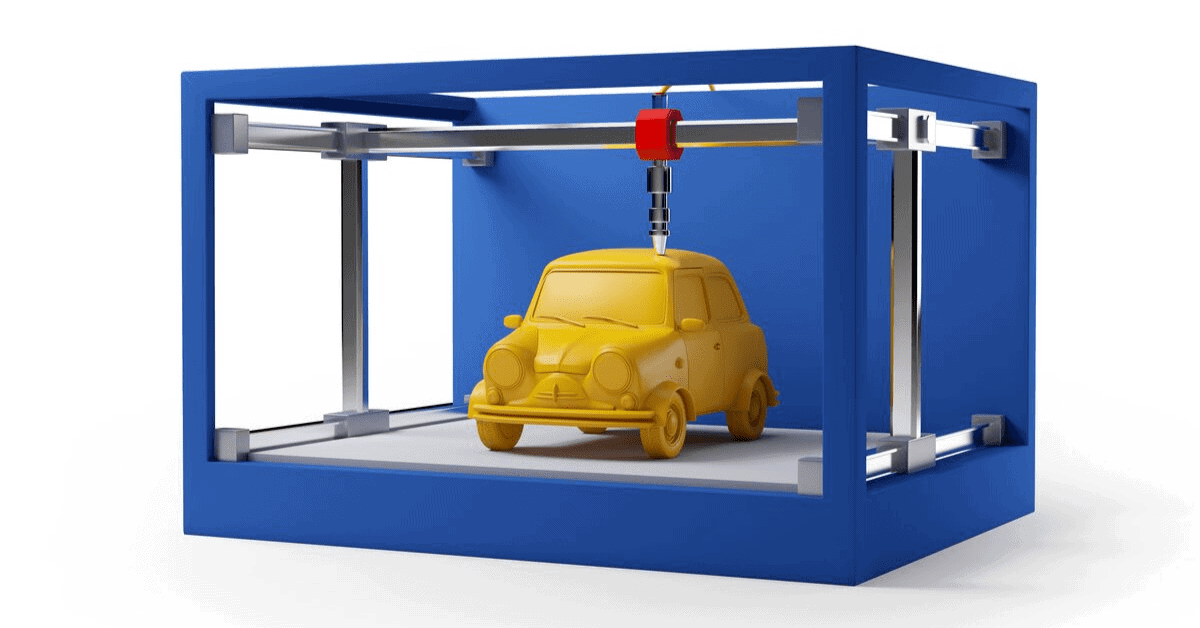

3D printers are the future in manufacturing, and their capabilities continue to improve. They can be utilized to design any object you want: cases for your phone, tablet or furniture, or figurines that can be given as gifts, and even musical instruments. There are a myriad of possibilities with these devices, but there are some basic things you should be aware of before you get started.

Types and uses of 3D printers

3D printers are among the most exciting technologies of the moment. They are able to produce physical objects with high accuracy and precision, making the perfect tool for architects that need to design models or designers who want to see how various materials look in their designs before creating them! There’s a specific kind of 3-dimensional printing machine though that is perhaps superior to any other: FDM (or “Fused Deposition Modeling”), an easy-to-use device that heats plastics until they shape themselves into whatever form you want This means that you don’t have to worry about needing to play around with various shapes. Just choose from preprogrammed choices like taco shells c payer boxes.

Printers designed to be custom-built

The decision to construct your 3D printer yourself or purchase one pre-assembled is crucial. Are you in a position to build it with enough time on hand? Do the skills needed for construction not within reachable distance, or because they’re difficult or not possible depending upon where in society that we live? If this sounds like something that you would like to learn about then look into purchasing suitable parts from someone who is already aware of what they require before heading out to stores for yourself. There are deals waiting on every corner.

Price

The 3D printer is an incredible technology that can create three-dimensional items using either plastic or metal. The prices for these machines vary depending on many factors , such as the their performance, but they usually are priced between $1000 to more than 2000 dollars! A drone kit with gyro, which costs only $100 could be a good option for someone who is just starting out.

Materials

3D printing is a revolutionary improvement in manufacturing. It allows for intricate objects to be manufactured with incredible clarity. Today, we’ll examine two common types of materials used during this period: Acrylonitrile Butadiene Styrene and Poly Lactic acid are both extremely soft upon heating but they will harden when cool; However, there are crucial aspects to consider prior to making your final choice! For instance there are some printers that work best with one material over another , so ensure that the one that works best will be able to produce what you need out of it too.

Safety

3D printers are able to make functional objects, and also to replicate human organs. They also release gasses that can make you sick or cause severe eye damage (such as with children). This is why I strongly suggest wearing a mask made of top quality materials when using one. It’s safe for all.

Qualitative

A high-quality printer will produce quality printed products. It is important to consider two aspects: Print Speed & Resolution. Print resolution is measured by microns. Quality prints will be created with lower numbers. The speed at which your machine moves ink around affects the speed at which your object is eventually printed and so make sure it is able to handle the load before starting any projects big or small. This front-line unit to capture life’s tiny moments.

For more information, click creatbot F430